I Overview

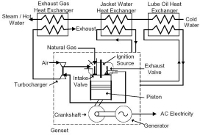

Natural gas reciprocating engines use fuel combustion to turn a crankshaft in order to generate motive power. Most engines operate using a four-stroke process, similar to the gasoline-powered engine in most automobiles.

II Applications

Small to medium sized engines are primarily designed for transportation applications and can be converted to power generation with little modification. Larger engines are, in general, designed for power generation, mechanical drive, or marine propulsion.

The waste heat generated by an engine is also usable for cogeneration. Heat recovery can produce a stream of hot water, either for direct use in building heating systems or for other hot water needs. Heat recovery can also produce low pressure steam instead of hot water. In some commercial and industrial settings, the flue gases provide both direct and indirect process heat.

III Equipment Options

Bi-fuel conversion allows the use of natural gas in an existing diesel engine. An externally-mounted device substitutes natural gas for up to 90% of the diesel fuel that the engine would otherwise consume. Depending on the relative costs of diesel and natural gas, the conversion can yield significant cost savings in addition to a reduction in emissions.

IV Resources

1. Equipment Manufacturer Database

2. Distributed Generation Consortium

V Photo